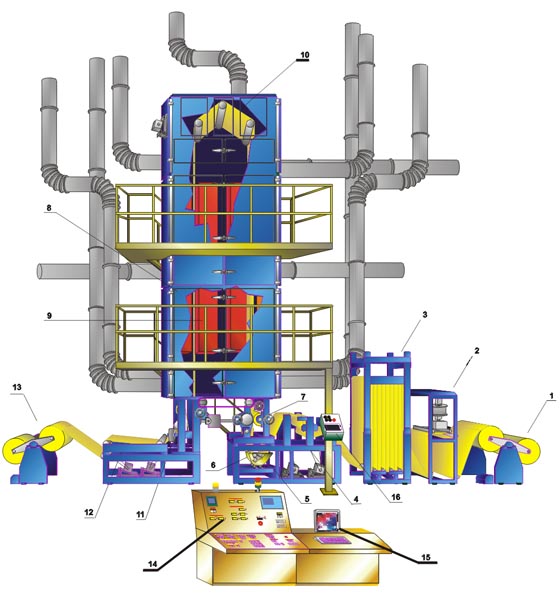

| Configuration |

|

| |

1. Unwind station equipped with double-shaft turret type unwinder. The uniform cloth tension is provided by AC regulated drive. Unwinding tension is adjustable, according to the requirements and web characteristics. |

|

| |

2. Bonding Unit is consisting of splicing press for bonding the web ends. It permits clean roll changes. |

|

| |

3. Accumulator ensures continuous glass process. This unit accumulates extra web during the splice-pressing operation without stopping the web running. |

|

| |

4. Pull-In Unit allows even tension. This unit is driven by AC servomotor. A dancer system controls this unit. |

|

| |

5. Impregnation Unit. The most important part in the process for impregnating resins varnish into web. For better impregnation there are several possibilities for guiding the web through the impregnating rolls. This system provides minimum yarn slippage and air entrapment in the web. |

|

| |

6. Bath Heating. Controlled system for regulating the resin temperature in the impregnating bath. |

|

| |

7. Metering Unit equipped with two steel grounded and hard chromium plated rolls. The gap between metering rolls is micrometer adjustable. This unit is driven by servomotor. |

|

| |

8. Vertical Curing Oven. Vertical type radiant curing oven wheres after the impregnation with resin the web is dried. The oven is equipped with radiant heaters and air distribution system. The preheated fresh air is blown in at low speed in laminar flow. The flows of the blowers are fully adjustable and controlled by the machine control system. |

|

| |

9. Radiation Panel System. Specially designed infrared radiant panels cure the web from both sides. This system maintains uniform temperature distribution over the entire surface of the web assuring uniform and high effective drying and curing. |

|

| |

10. Deviation Zone. This unit is equipped with water-cooled rolls that reverse the web without adhesion. Additional fresh air blower supports web cooling. |

|

| |

11. Cooling Unit. Driven by AC servomotor this unit unwinds the web under the precision dancer tension control. Water-cooled roll part of this unit. |

|

| |

12. Edge Aligning System. Pneuma-hydraulic edge aligning system. With continuously monitoring of the web edge position via air nozzle sensors the web is kept running at roll center. |

|

| |

13. Rewind Station. AC regulated drive provide control of the winding speed and tension. |

|

| |

14. Control Cabinet. Equipped with Operator Panel and Recorder. |

|

| |

15. SCADA System. Specially designed application based on HMI (Human Machine Interface) and SCADA (supervisory control and data acquisition) ensures high level of control to the whole production process. |

|

| |

16. Operator Console. For easy operation the main commands are available on the machine. |

|

| |

|